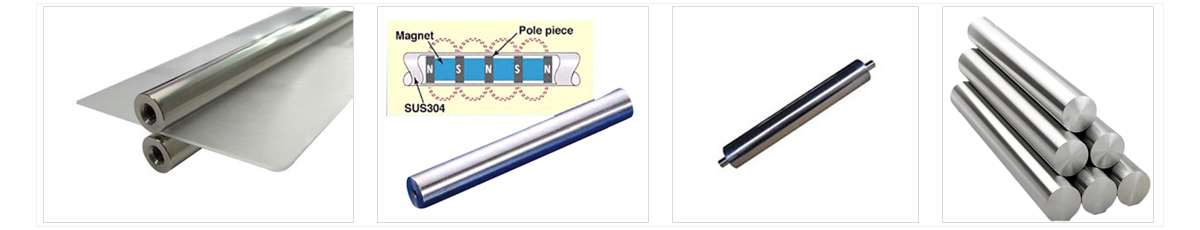

2. Magnetic coupler/coupling: A magnetic coupler is a device that uses a magnetic field to transmit power and torque between two shafts. It usually consists of two magnetic coupler sections, one mounted on the drive shaft and one mounted on the driven shaft. There is no mechanical contact between these two parts, and the transmission of power and torque is done through magnetic interaction.

The design principle of the magnetic coupler is to convert the rotational power of the drive shaft into a magnetic field through the magnetic force, and then act on the magnetic coupler of the driven shaft through the magnetic field, so as to realize the transmission between the two shafts. The magnetic coupling does not require mechanical contact, so it can avoid the wear of traditional mechanical parts such as bearings and seals, and can also prevent liquid or gas leakage. This makes magnetic couplers particularly suitable for applications with high precision, high reliability, and high hygiene.

Magnetic couplers have many advantages, such as no contact, no wear, no friction, good sealing, etc. Therefore, it is widely used in many fields, such as chemical industry, medicine, food, water treatment, semiconductor manufacturing, aerospace and so on.